Diving into Fleet Preventive Maintenance Schedules Every Manager Should Know, this introduction provides a comprehensive look at the importance of maintaining fleet vehicles. It covers key components of preventive maintenance schedules and common tasks involved, setting the stage for a detailed exploration ahead.

Fleet Preventive Maintenance Schedules Overview

Preventive maintenance is crucial for fleet vehicles to ensure they remain reliable, safe, and efficient on the road. By implementing a well-rounded preventive maintenance schedule, fleet managers can minimize unexpected breakdowns, reduce repair costs, and extend the lifespan of their vehicles.

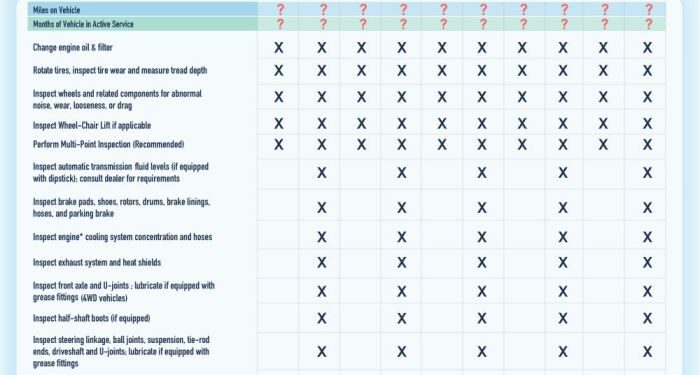

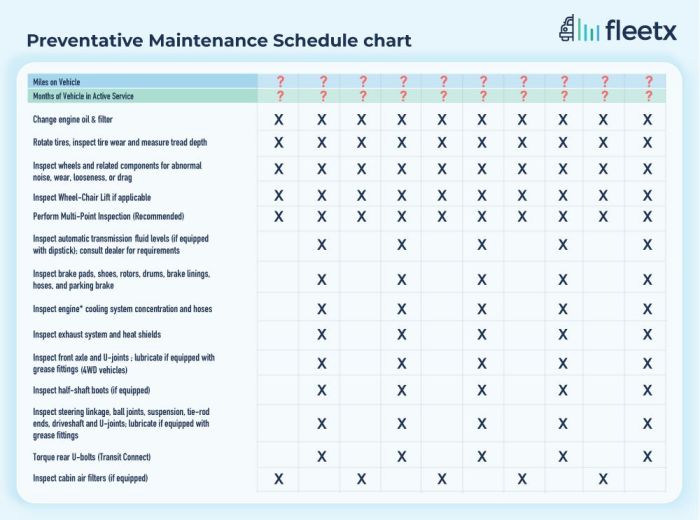

Key Components of a Well-Rounded Preventive Maintenance Schedule

- Regular inspections: Conducting routine inspections of fleet vehicles to identify any potential issues before they escalate.

- Fluid checks and changes: Checking and changing fluids such as oil, coolant, and brake fluid to keep the engine running smoothly.

- Tire maintenance: Rotating tires, checking tire pressure, and ensuring proper alignment to improve fuel efficiency and traction.

- Brake system checks: Inspecting brake pads, rotors, and brake lines to maintain optimal braking performance.

Examples of Common Preventive Maintenance Tasks for Fleet Vehicles

- Oil changes: Regularly changing the engine oil and oil filter to prevent engine wear and overheating.

- Air filter replacement: Replacing the air filter to ensure clean air intake and improve engine performance.

- Battery checks: Inspecting the battery for corrosion, leaks, and proper connection to avoid unexpected breakdowns.

- Light inspections: Checking all lights, including headlights, brake lights, and turn signals, to maintain visibility and safety on the road.

Setting Up a Preventive Maintenance Program

Setting up a preventive maintenance program is crucial for ensuring the efficient operation of a fleet. By implementing a comprehensive program, managers can minimize downtime, reduce repair costs, and prolong the lifespan of vehicles.

Role of Technology in Scheduling and Tracking Maintenance Tasks

Technology plays a vital role in modern preventive maintenance programs, offering tools for scheduling and tracking maintenance tasks efficiently. Fleet management software allows managers to create maintenance schedules, set reminders for upcoming services, and track maintenance history for each vehicle.

- Utilize fleet management software to automate maintenance schedules and reminders.

- Implement GPS tracking to monitor vehicle usage and performance in real-time.

- Use telematics systems to collect data on vehicle health and performance for proactive maintenance planning.

Tips on Prioritizing Maintenance Tasks

Prioritizing maintenance tasks based on vehicle usage and age is essential for optimizing fleet performance and safety. By understanding which vehicles require immediate attention, managers can allocate resources effectively and minimize the risk of breakdowns.

- Focus on high-mileage vehicles that are more prone to wear and tear.

- Prioritize maintenance tasks for older vehicles to prevent costly repairs and extend their lifespan.

- Consider the specific needs of each vehicle type (e.g., heavy-duty trucks vs. passenger vehicles) when setting maintenance priorities.

Frequency of Preventive Maintenance Checks

Regular preventive maintenance checks are crucial for keeping fleet vehicles in optimal condition and minimizing unexpected breakdowns

Frequency Based on Vehicle Type and Usage

The frequency of preventive maintenance checks may vary depending on the type of vehicle and its usage. Here are some general guidelines:

- Light-Duty Vehicles:For sedans and light trucks used for daily commuting or short trips, preventive maintenance checks are usually recommended every 5,000 to 7,500 miles or every 6 months.

- Medium-Duty Vehicles:Vehicles such as vans or medium-sized trucks used for deliveries or service calls may require preventive maintenance checks every 10,000 to 15,000 miles or every 6 months.

- Heavy-Duty Vehicles:Trucks, buses, or vehicles used for long-haul transportation should undergo preventive maintenance checks every 20,000 to 30,000 miles or every 6 months.

Sample Preventive Maintenance Schedule Template

| Vehicle Type | Frequency (Miles) | Frequency (Months) |

|---|---|---|

| Light-Duty | 5,000

| 6 |

| Medium-Duty | 10,000

| 6 |

| Heavy-Duty | 20,000

| 6 |

Benefits of Adhering to Preventive Maintenance Schedules

Adhering to preventive maintenance schedules for fleet vehicles offers numerous advantages that can significantly impact the efficiency and longevity of the vehicles.

Reduced Downtime and Extended Vehicle Lifespan

Proper adherence to preventive maintenance schedules helps in identifying and addressing potential issues before they escalate into major problems. By conducting regular inspections and servicing according to a set schedule, fleet managers can prevent unexpected breakdowns and reduce downtime. This proactive approach not only keeps the vehicles on the road but also extends their lifespan by ensuring that all components are well-maintained and functioning optimally.

- Regular oil changes and filter replacements can prevent engine wear and improve fuel efficiency.

- Checking and maintaining tire pressure can enhance safety, reduce the risk of blowouts, and prolong tire life.

- Scheduled inspections of brakes and suspension systems can prevent accidents and costly repairs.

Cost Savings Achieved Through Proper Preventive Maintenance

Adhering to preventive maintenance schedules can result in significant cost savings for fleet operations. By investing in regular maintenance, fleet managers can avoid expensive repairs, replacements, and unexpected downtime that may disrupt business operations and incur additional costs.

For example, a study conducted by a major fleet management company revealed that for every dollar invested in preventive maintenance, fleets saved an average of $5 in repair and replacement costs.

- Preventive maintenance reduces the likelihood of major breakdowns, which can be more costly to repair compared to minor issues detected early.

- Well-maintained vehicles are more fuel-efficient, saving on operational costs in the long run.

- By extending the lifespan of vehicles through preventive maintenance, fleets can delay the need for new vehicle purchases, saving on capital expenditures.

Epilogue

In conclusion, Fleet Preventive Maintenance Schedules Every Manager Should Know are crucial for ensuring the longevity and efficiency of fleet vehicles. By adhering to these schedules, managers can minimize downtime, extend vehicle lifespans, and ultimately save costs in the long run.

Question Bank

How often should preventive maintenance be conducted?

It is recommended to conduct preventive maintenance checks on fleet vehicles every 3,000 to 5,000 miles, but this can vary based on usage and vehicle type.

What are the benefits of following preventive maintenance schedules?

Adhering to preventive maintenance schedules can lead to reduced downtime, extended vehicle lifespan, and significant cost savings in the long term.